Sunday, December 25, 2011

Sunday, December 18, 2011

Saturday, December 17, 2011

Thursday, December 8, 2011

Wednesday, November 9, 2011

Monday, November 7, 2011

Friday, October 7, 2011

Thursday, August 25, 2011

Wednesday, August 3, 2011

Gas dryer fixed!

Monday, July 25, 2011

Thursday, July 21, 2011

Samsung Ice box Thermistor location

http://www.blogger.com/img/blank.gif

http://www.blogger.com/img/blank.gifClick on pic twice to enlarge.

Samsung Side by side ice box service manual

Thursday, July 14, 2011

Old school 2 belt maytag washer de-mystified!

Monday, July 11, 2011

Monday, July 4, 2011

Danby DIM1524W Stand alone ice maker User Manual

User manual for Danby portable ice makerhttp://www.blogger.com/img/blank.gif

Wednesday, June 29, 2011

Tuesday, June 28, 2011

Friday, June 24, 2011

Wednesday, June 22, 2011

Friday, June 17, 2011

Monday, June 13, 2011

Saturday, June 11, 2011

Thursday, June 9, 2011

Wednesday, June 8, 2011

Window AC freeze over blues

Tuesday, June 7, 2011

Hot wired window unit

Today I hot wired another window unit. The electronics and fan had failed. The compressor and sealed system worked great. So why toss it? I added a fan motor from another unit with bad compressor and hard wired it to work anywhere cooling is needed. Just plug it in the wall to turn it on, get too cold unplug it! OR A simple low voltage relay with transformer and wall t-stat will control the temp. OR yall could rig most any old cold control to break the power when the desired temp is reached.

Their are 2 kinds of peeps in the world.

Them that has AC and them that don't!

Quote me on that will ya?

Wiring is simple. The power cord has a green "GROUND" wire, a white "COMMON" wire and a black "Hot" wire. The white goes to capacitor, the black goes with compressor run wire and any fan speed (I chose HI speed). The LOW and MED speeds are live and must be taped off separately and away from the frame.

Captain's log supplemental:

Today I added a cold control to the unit. On the unit is a junction block with 2 separate gangs of spade connectors. The gang to the right is empty. The gang to the left has a black HOT wire and a black HI speed fan wire and a RUN wire from the compressor. I simply remove the hot wire and placed it next door in the empty gang. I attached a wired from the cold control also. The other cold control wire I added back to the connector that I removed the power wire from. Now the unit will cycle on and off when the house gets cold.

Video:

Their are 2 kinds of peeps in the world.

Them that has AC and them that don't!

Quote me on that will ya?

Wiring is simple. The power cord has a green "GROUND" wire, a white "COMMON" wire and a black "Hot" wire. The white goes to capacitor, the black goes with compressor run wire and any fan speed (I chose HI speed). The LOW and MED speeds are live and must be taped off separately and away from the frame.

Captain's log supplemental:

Today I added a cold control to the unit. On the unit is a junction block with 2 separate gangs of spade connectors. The gang to the right is empty. The gang to the left has a black HOT wire and a black HI speed fan wire and a RUN wire from the compressor. I simply remove the hot wire and placed it next door in the empty gang. I attached a wired from the cold control also. The other cold control wire I added back to the connector that I removed the power wire from. Now the unit will cycle on and off when the house gets cold.

Video:

Monday, June 6, 2011

Sunday, June 5, 2011

Wednesday, May 25, 2011

Saturday, May 21, 2011

Friday, May 20, 2011

Wednesday, May 11, 2011

Tuesday, May 10, 2011

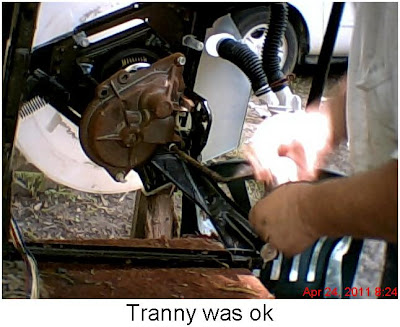

Direct drive photos

Did a few photos of the tranny removal and spin tube and such. Once you remove the agitator the tranny will slide out after removing 3 bolts. The spin tube will come out IF you remove the inner basket which you should do first when looking for reasons why she won't spin. As you can see this is not a very complicated washer.

Sunday, May 8, 2011

Saturday, May 7, 2011

Tuesday, May 3, 2011

Monday, May 2, 2011

Tuesday, April 19, 2011

Scotsman Ice Machine Revamp

I worked on a Scotsman ice maker over the weekend. I let it run 24 hours starting Thursday night. Friday morning nary an ice cube. This ice maker has an inverted mold. 2 spray nozzle continually supply water to the mold. When the cubes have formed the ice maker shuts down and flushes the res with water while flushing the mold with hot gas. The cubes fall out of the mold and into the bin. Every 20 minutes 6 new ice cubes are made. I had an idea this one was low of gas. Not very much heat coming from the condenser area and the water was cold but not freezing my fingertips. The machine runs on R134A gas. It only holds 5 ounces of freon. It already has some in it. If overcharged the line will be blocked and the compressor will bog down. So how much do you add? I attached a saddle valve and found the system was running in vacuum or in other words negative 10 PSI on the low side. I SLOWLY added a tiny amount of gas never letting the needle get above 10 PSI. When the pressure hung in there around 5 PSI without imediately going back into negative I quit adding and waited. It slowly dropped to 1PSI and stayyed there. In a minute or 2 it shut down and flushed the reservoir, shot hot gas into the mold and loosened up the ice. In the world of dead ice machines hearing the magic ka-thunk of an ice cube hitting an empty bin is a good thing!

Sunday, April 17, 2011

Friday, April 15, 2011

Monday, April 11, 2011

Friday, April 8, 2011

Duet HE Front Load Washer GHW9150P Error Codes

FH: If after 30 seconds the control does not detect water entering

machine, the valves will be turned off and the error code will be

displayed. OR If the control has turned the water valves on and after

8 minutes the flow sensor has detected 10.5 gallons of water passing through it, but has not detected the pressure switch trip, the valves will be turned off and the error code will flash.

Press PAUSE/CANCEL twice to clear the display.

If there is no water in the unit:

—Make sure that both valves at the water source(s) are turned

on all the way.

—Check for plugged or kinked inlet hoses or plugged screens in

the inlet valves.

—Verify inlet valve operation.

If there is water in the unit:

—Verify drain pump operation.

—Verify that the pressure switch hose is in good condition and

properly connected to tub and pressure switch.

1. Verify there is not a siphon problem.

2. Unplug washer or disconnect power.

3. Verify wire harness connections to inlet valves,

pressure switch, drain pump, flow meter, and

Central Control Unit (CCU).

4. Check all hoses for possible leaks.

5. Plug in washer or reconnect power

6. Verify pressure switch operation.

7. Verify flow meter operation by blowing air through the part and

measuring the resistance.

8. Verify CCU operation by running a Diagnostic test or any cycle.

F-2 Long Drain

If the drain time exceeds eight minutes, the water valves are turned off

and “F/02” is flashed. Press PAUSE/CANCEL two times to clear the

display.

NOTE: After four minutes the “Sud” error will be displayed, then four

minutes later the “F/02” error code will be displayed.

1. Check the drain hose and make sure it is not plugged

or kinked.

2. Unplug washer or disconnect power.

3. Check the electrical connections at the pump and

make sure the pump is running.

4. Check the drain pump filter for foreign objects.

5. Plug in washer or reconnect power.

6. If the above does not correct the problem, go to step 7.

7. Unplug washer or disconnect power.

8. Replace the pump.

F-5 Water temp sensor failure

If during the water heating step in the wash cycle, the water

temperature sensor (NTC) value is out of range, the “F/05” error code

will be displayed. Possible cause/procedure:

1. Unplug washer or disconnect power.

2. Check the water temperature sensor. Refer to the

“Water Temperature Sensor” section. Check

connections to the water temperature sensor.

3. Check resistance of heating element, if present on this

model. (abnormal = infinity)

F-06 Drive motor Tachometer error

Possible causes/procedure:

1. Verify the shipping system including shipping bolts, spacers

and cables are removed.

2. Unplug washer or disconnect power.

3. Check wire harness connections between the drive motor and

the Motor Control Unit (MCU), and between the MCU and the

Central Control Unit (CCU).

4. Plug in washer or reconnect power.

5. Check the MCU by looking for operations of the drive motor.

6. Check the drive motor for powered rotations.

F-07 Motor control unit error

Possible causes/procedure:

1. Unplug washer or disconnect power.

2. Check wire harness connections between the drive motor and

the Motor Control Unit (MCU), and between the MCU and the

Central Control Unit (CCU).

3. Plug in washer or reconnect power.

4. Check the MCU by looking for operations of the drive motor.

5. Check the drive motor for powered rotations.

F-09 Overflow Condition

Possible causes/procedure:

1. Check the drain hose and make sure it is not plugged

or kinked.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the drain pump,

pressure switch, and Central Control Unit (CCU).

4. Check/clean drain pump filter of foreign objects.

5. Check for drain pump failure.

6. Check the inlet valve for proper shut off.

7. the pressure switch for proper operation.

F10 Motor control unit heat sink thermal trip

Possible causes/procedure:

1. Check for proper installation, verify the unit is not located

near a source of heat and has proper ventilation.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the MCU, the motor,

and Central Control Unit (CCU).

4. Check the drive system for any worn or failed components.

5. Plug in washer or reconnect power.

6. Check the MCU by looking for operations of the drive motor.

7. Check the drive motor for powered rotations.

F11 Serial communication error

Communication between the Central Control Unit (CCU) and the

Motor Control Unit (MCU) cannot be sent correctly.

Possible causes/procedure:

1. Unplug washer or disconnect power.

2. Check wire harness connections to the MCU, the motor, and

Central Control Unit (CCU).

3. Check the drive system for any worn or failed components.

4. Plug in washer or reconnect power.

5. Verify CCU operation by running a Diagnostic test or any

cycle.

6. Check the MCU by looking for operations of the drive motor.

7. Check the drive motor for powered rotations.

8. Check that the serial harness at the MCU is not mounted

upside down. The wires should be to the left when facing the

MCU connectors.

F13 Dispenser circuit error

Possible causes/procedure:

1. Unplug washer or disconnect power.

2. Check mechanical linkage from dispenser motor to the top of

the dispenser.

3. Check wire harness connections to the dispenser motor and

Central Control Unit (CCU).

4. Check dispenser motor for powered rotations.

F14 The dreaded EEPROM error

The Central Control Unit (CCU) receives its data from an EEPROM

on board the CCU. If there is an error reading this data it will cause this

error. Possible causes/procedure:

¦ A power glitch may cause this error.

1. Unplug washer or disconnect power for two minutes.

2. Verify CCU operation by running a Diagnostic test or any

cycle.

F15 Motor control unit error

If the MCU detects multiple resets or errors during a wash cycle it will

go into this error mode. Possible causes/proceedure:

1. Unplug washer or disconnect power.

2. Check wire harness connections to the MCU, the motor, and

Central Control Unit (CCU).

3. Check drive belt.

4. Plug in washer or reconnect power.

5. Check the MCU by looking for operations of the drive motor.

6. Check the drive motor for powered rotations.

F21 F 22 CCU /touchpad/LED assembly unable to transmit/receive data to/from the CCU central control unit

Possible causes/procedure:

1. Check the touch-pad/LED assembly by selecting different

cycles and changing the modifiers and options available to

confirm the touch-pad/LED is responding.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the

touch-pad/LED assembly and Central Control Unit (CCU).

F du Door unlock error

A Door Unlock Error occurs if the door cannot be unlocked. It will try to

unlock the door 6 times before displaying the error code.

Possible causes/procedure:

¦ Door lock mechanism is broken.

¦ Door switch/lock unit failure.

1. Check door switch/lock unit for foreign objects.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the door switch/lock

unit and Central Control Unit (CCU).

NOTE: The door switch/lock unit can be manually unlocked. See

“Manually Unlocking The Door Lock System”.

F dl Door lock error

A Door Lock Error occurs if the door cannot be locked. It will try to lock

it six times before displaying the error code.

Possible causes/procedure:

¦ Door lock mechanism is broken or removed from door.

¦ Door switch/lock unit failure.

1. Unplug washer or disconnect power.

2. Check door switch/lock unit.

3. Check the wire harness connections to the door

switch/lock unit and Central Control Unit (CCU).

Sud: Suds lock (overdose of detergent detected during wash cycle)

The motor control unit senses a suds lock condition by analyzing the

current draw on the drive motor. If “Sud” is displayed a potential Suds

Lock is detected. This may signify a bad pump, an extra heavy load,

excessive detergent, or excessive suds.

Possible causes/procedure:

¦ If too much detergent was used:

—Run the unit through a Rinse/Spin cycle.

—Run a Normal cycle without adding any detergent.

This should clear the unit of the excess detergent.

1. Check the drain hose and make sure it is not plugged

or kinked.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the drain pump,

pressure switch, and Central Control Unit (CCU).

4. Check/clean drain pump filter of foreign objects.

5. Plug in washer or reconnect power.

6. Check drain pump.

7. Check the pressure switch.

8. Verify CCU operation by running a Diagnostic test or any

cycle.

machine, the valves will be turned off and the error code will be

displayed. OR If the control has turned the water valves on and after

8 minutes the flow sensor has detected 10.5 gallons of water passing through it, but has not detected the pressure switch trip, the valves will be turned off and the error code will flash.

Press PAUSE/CANCEL twice to clear the display.

If there is no water in the unit:

—Make sure that both valves at the water source(s) are turned

on all the way.

—Check for plugged or kinked inlet hoses or plugged screens in

the inlet valves.

—Verify inlet valve operation.

If there is water in the unit:

—Verify drain pump operation.

—Verify that the pressure switch hose is in good condition and

properly connected to tub and pressure switch.

1. Verify there is not a siphon problem.

2. Unplug washer or disconnect power.

3. Verify wire harness connections to inlet valves,

pressure switch, drain pump, flow meter, and

Central Control Unit (CCU).

4. Check all hoses for possible leaks.

5. Plug in washer or reconnect power

6. Verify pressure switch operation.

7. Verify flow meter operation by blowing air through the part and

measuring the resistance.

8. Verify CCU operation by running a Diagnostic test or any cycle.

F-2 Long Drain

If the drain time exceeds eight minutes, the water valves are turned off

and “F/02” is flashed. Press PAUSE/CANCEL two times to clear the

display.

NOTE: After four minutes the “Sud” error will be displayed, then four

minutes later the “F/02” error code will be displayed.

1. Check the drain hose and make sure it is not plugged

or kinked.

2. Unplug washer or disconnect power.

3. Check the electrical connections at the pump and

make sure the pump is running.

4. Check the drain pump filter for foreign objects.

5. Plug in washer or reconnect power.

6. If the above does not correct the problem, go to step 7.

7. Unplug washer or disconnect power.

8. Replace the pump.

F-5 Water temp sensor failure

If during the water heating step in the wash cycle, the water

temperature sensor (NTC) value is out of range, the “F/05” error code

will be displayed. Possible cause/procedure:

1. Unplug washer or disconnect power.

2. Check the water temperature sensor. Refer to the

“Water Temperature Sensor” section. Check

connections to the water temperature sensor.

3. Check resistance of heating element, if present on this

model. (abnormal = infinity)

F-06 Drive motor Tachometer error

Possible causes/procedure:

1. Verify the shipping system including shipping bolts, spacers

and cables are removed.

2. Unplug washer or disconnect power.

3. Check wire harness connections between the drive motor and

the Motor Control Unit (MCU), and between the MCU and the

Central Control Unit (CCU).

4. Plug in washer or reconnect power.

5. Check the MCU by looking for operations of the drive motor.

6. Check the drive motor for powered rotations.

F-07 Motor control unit error

Possible causes/procedure:

1. Unplug washer or disconnect power.

2. Check wire harness connections between the drive motor and

the Motor Control Unit (MCU), and between the MCU and the

Central Control Unit (CCU).

3. Plug in washer or reconnect power.

4. Check the MCU by looking for operations of the drive motor.

5. Check the drive motor for powered rotations.

F-09 Overflow Condition

Possible causes/procedure:

1. Check the drain hose and make sure it is not plugged

or kinked.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the drain pump,

pressure switch, and Central Control Unit (CCU).

4. Check/clean drain pump filter of foreign objects.

5. Check for drain pump failure.

6. Check the inlet valve for proper shut off.

7. the pressure switch for proper operation.

F10 Motor control unit heat sink thermal trip

Possible causes/procedure:

1. Check for proper installation, verify the unit is not located

near a source of heat and has proper ventilation.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the MCU, the motor,

and Central Control Unit (CCU).

4. Check the drive system for any worn or failed components.

5. Plug in washer or reconnect power.

6. Check the MCU by looking for operations of the drive motor.

7. Check the drive motor for powered rotations.

F11 Serial communication error

Communication between the Central Control Unit (CCU) and the

Motor Control Unit (MCU) cannot be sent correctly.

Possible causes/procedure:

1. Unplug washer or disconnect power.

2. Check wire harness connections to the MCU, the motor, and

Central Control Unit (CCU).

3. Check the drive system for any worn or failed components.

4. Plug in washer or reconnect power.

5. Verify CCU operation by running a Diagnostic test or any

cycle.

6. Check the MCU by looking for operations of the drive motor.

7. Check the drive motor for powered rotations.

8. Check that the serial harness at the MCU is not mounted

upside down. The wires should be to the left when facing the

MCU connectors.

F13 Dispenser circuit error

Possible causes/procedure:

1. Unplug washer or disconnect power.

2. Check mechanical linkage from dispenser motor to the top of

the dispenser.

3. Check wire harness connections to the dispenser motor and

Central Control Unit (CCU).

4. Check dispenser motor for powered rotations.

F14 The dreaded EEPROM error

The Central Control Unit (CCU) receives its data from an EEPROM

on board the CCU. If there is an error reading this data it will cause this

error. Possible causes/procedure:

¦ A power glitch may cause this error.

1. Unplug washer or disconnect power for two minutes.

2. Verify CCU operation by running a Diagnostic test or any

cycle.

F15 Motor control unit error

If the MCU detects multiple resets or errors during a wash cycle it will

go into this error mode. Possible causes/proceedure:

1. Unplug washer or disconnect power.

2. Check wire harness connections to the MCU, the motor, and

Central Control Unit (CCU).

3. Check drive belt.

4. Plug in washer or reconnect power.

5. Check the MCU by looking for operations of the drive motor.

6. Check the drive motor for powered rotations.

F21 F 22 CCU /touchpad/LED assembly unable to transmit/receive data to/from the CCU central control unit

Possible causes/procedure:

1. Check the touch-pad/LED assembly by selecting different

cycles and changing the modifiers and options available to

confirm the touch-pad/LED is responding.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the

touch-pad/LED assembly and Central Control Unit (CCU).

F du Door unlock error

A Door Unlock Error occurs if the door cannot be unlocked. It will try to

unlock the door 6 times before displaying the error code.

Possible causes/procedure:

¦ Door lock mechanism is broken.

¦ Door switch/lock unit failure.

1. Check door switch/lock unit for foreign objects.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the door switch/lock

unit and Central Control Unit (CCU).

NOTE: The door switch/lock unit can be manually unlocked. See

“Manually Unlocking The Door Lock System”.

F dl Door lock error

A Door Lock Error occurs if the door cannot be locked. It will try to lock

it six times before displaying the error code.

Possible causes/procedure:

¦ Door lock mechanism is broken or removed from door.

¦ Door switch/lock unit failure.

1. Unplug washer or disconnect power.

2. Check door switch/lock unit.

3. Check the wire harness connections to the door

switch/lock unit and Central Control Unit (CCU).

Sud: Suds lock (overdose of detergent detected during wash cycle)

The motor control unit senses a suds lock condition by analyzing the

current draw on the drive motor. If “Sud” is displayed a potential Suds

Lock is detected. This may signify a bad pump, an extra heavy load,

excessive detergent, or excessive suds.

Possible causes/procedure:

¦ If too much detergent was used:

—Run the unit through a Rinse/Spin cycle.

—Run a Normal cycle without adding any detergent.

This should clear the unit of the excess detergent.

1. Check the drain hose and make sure it is not plugged

or kinked.

2. Unplug washer or disconnect power.

3. Check wire harness connections to the drain pump,

pressure switch, and Central Control Unit (CCU).

4. Check/clean drain pump filter of foreign objects.

5. Plug in washer or reconnect power.

6. Check drain pump.

7. Check the pressure switch.

8. Verify CCU operation by running a Diagnostic test or any

cycle.

Wednesday, March 30, 2011

Tuesday, March 29, 2011

Sunday, March 27, 2011

Saturday, March 26, 2011

Sunday, March 20, 2011

Wednesday, March 16, 2011

Tuesday, March 15, 2011

Friday, March 11, 2011

Wednesday, March 9, 2011

Saturday, March 5, 2011

Blodgett Pizza Oven Parts Manual

Blodgett Pizza oven parts Manual

Blodgett installation and trouble shooting guide

Bonus info. Since all auto pilot systems use basically the same prinicible I thought I might add this from RobertShaw. Although products may differ in parts and appearance, they all work the same way. The spark/sensor does 2 jobs. Lights the pilot and then monitors the flame:

Kanthal Spark/sensor Ignition info

Blodgett installation and trouble shooting guide

Bonus info. Since all auto pilot systems use basically the same prinicible I thought I might add this from RobertShaw. Although products may differ in parts and appearance, they all work the same way. The spark/sensor does 2 jobs. Lights the pilot and then monitors the flame:

Kanthal Spark/sensor Ignition info

Thursday, March 3, 2011

Saturday, February 26, 2011

Thursday, February 17, 2011

Monday, February 14, 2011

Tuesday, February 8, 2011

Monday, February 7, 2011

Sunday, February 6, 2011

Friday, February 4, 2011

Wednesday, February 2, 2011

Sunday, January 30, 2011

Dot dryer late model belt replacement video

This dryer is currently being sold under the Maytag and Whirlpool name and features a front panel kickplate for ease of servicing and 4 wheel drum suppor:

Friday, January 28, 2011

Thursday, January 27, 2011

Wednesday, January 26, 2011

Main drive gear worn smooth on direct drive tranny

Here is a rare but nice short and sweet video which shows a worn main drive gear on a Kenmore direct drive washer. This is an easy fix. All you need is some snap ring pliers. The new part comes with a drive gear and pinion. $63 bucks

Tuesday, January 25, 2011

Friday, January 14, 2011

Saturday, January 8, 2011

Monday, January 3, 2011

Saturday, January 1, 2011

Subscribe to:

Posts (Atom)